If you've been researching CAD-ERP integration solutions, you've probably noticed something frustrating: it's nearly impossible to get a straight answer on pricing. Every vendor seems to say "it depends" when you ask for costs.

How do we know that's the case? Well... that's been our answer for a long time, too!

Here's the thing, though. That answer - "it depends" - is accurate, and that's actually good news for you.

How so?

CAD-ERP integration pricing varies because solutions must match your specific technical complexity and automation maturity level. Rather than forcing you into a one-size-fits-all solution, this variability ensures you only pay for capabilities you actually need while providing a clear upgrade path as your business grows.

Before we dive into pricing complexity, let's establish what's at stake.

The Real Cost of Broken CAD-ERP Workflows

Manual CAD-to-ERP data transfer isn't just inefficient. It's expensive:

- Time drain: Engineers spending 8+ hours weekly on data entry instead of design

- Error costs: A single manufacturing mistake from incorrect BOM data can cost $5,000-$25,000

- Missed opportunities: Delayed product launches while engineers manually update thousands of parts

- Scale limitations: Can't grow your product line because your processes don't scale

For a 10-engineer team, we're talking about $200,000+ annually in wasted productivity. That doesn't even account for error costs and missed market opportunities.

Why CAD-ERP Integration Pricing is Complex (And Why That's Good)

Unlike simple software licenses, CAD-ERP integration touches every aspect of your engineering and manufacturing workflow. And since different organizations have varying levels of complexity, the pricing naturally reflects that real-world variability. So what are some of things that move the needle?

TECHNICAL COMPLEXITY FACTORS

ERP System Architecture: A NetSuite implementation looks nothing like an IFS deployment. Different ERPs have vastly different data structures, field requirements, and business logic capabilities.

CAD Environment Diversity: Are you running solely on SolidWorks, or do you have a mix of Inventor, Creo, and legacy CAD files? Each system requires different extraction methods and data handling.

Data Volume and Structure: Processing 100 simple parts weekly is different from handling 15,000+ complex assemblies with multi-level BOMs, custom materials, and routing requirements.

Business Logic Requirements: Basic field mapping versus complex conditional logic, multi-site deployment, and PLM integration all require different technical approaches.

BUSINESS MATURITY FACTORS

Automation Readiness: Teams just starting their digital transformation journey need different solutions than those ready for "do it while we sleep" automation.

Process Standardization: Companies with established engineering standards can leverage pre-built templates, while those still developing standards need more configuration flexibility.

Growth Trajectory: A startup planning to 5x their engineering team in two years needs different capabilities than an established manufacturer optimizing existing processes.

Now let's look at how we deal with all these variables here at CADTALK.

The Four Levels of CAD-ERP Integration Maturity

Understanding where you are (and where you want to be) in your automation journey is key to selecting the right solution tier.

Launch (Essentials): Breaking Free from Manual Entry Hell

Who It's For: Teams drowning in spreadsheets and manual data entry

What's In the Box:

- Direct CAD-to-ERP data transfer with field mapping

- Visual change tracking with color-coded indicators

- Support for one CAD system and standard ERP objects

- Manual addition capabilities for hardware not in CAD models

- Basic validation and error checking before ERP transfer

What It Means for You:

- Transform 15-20 minute BOM updates into 2-3 minute reviews

- Eliminate transcription errors that cause manufacturing rework

- Free up 8+ hours per engineer weekly from administrative tasks

- Establish foundation for process standardization

Sample Scenario: A 5-engineer team using SolidWorks and Acumatica eliminates weekend overtime spent on BOM updates, saving $40,000 annually in labor costs while preventing two major manufacturing errors worth $15,000 each.

How Much It Costs: Starting at $8,000 annually

Implementation Scope: 8-10 weeks with pre-configured templates and standard field mappings.

Optimize (Growth): Enforcing Standards and Scaling Processes

Who It's For: Growing teams wanting consistent processes and error prevention

What's In the Box:

- Light automation with configurable business rules

- Part number reservation and duplicate prevention

- Option to add support for PDM systems and enhanced field logic

- Template customization for common scenarios

- Enhanced data validation and compliance checking

What It Means for You:

- Reduce rework costs by 60% through error prevention

- Handle 2x current volume with same team size

- Enforce company standards automatically across all projects

- Eliminate duplicate part number headaches

Sample Scenario: A 12-engineer team with SolidWorks PDM and Epicor implements automated part numbering standards, preventing duplicate parts that were costing $25,000 annually in excess inventory while reducing new product introduction time by 30%.

How Much It Costs: Starting at $10,000 annually

Implementation Scope: 14-16 weeks with custom template development and rule configuration.

Automate (Advanced): Mastering Complex Manufacturing Logic

Who It's For: Multi-site manufacturers with complex processes and PLM integration needs

What's In the Box:

- Moderate rules logic with conditional processing

- Multi-site BOM deployment and management

- Option to add PLM integration with bi-directional data flow

- Raw material calculations and advanced routing logic

- Support for multiple CAD systems and custom ERP objects

What It Means for You:

- Process 15,000+ SKUs without overtime or new hires

- Reduce multi-site setup time by 80%

- Eliminate 2-4 hours weekly of ERP-PLM reconciliation

- Save 15-20 minutes per assembly on raw material calculations

Sample Scenario: A global manufacturer with Windchill PLM and IFS deploys new product BOMs across 6 manufacturing sites simultaneously, reducing ECN processing time from weeks to hours while maintaining perfect data consistency across locations.

How Much It Costs: Starting at $13,000 annually

Implementation Scope: 5-6 months with advanced rule development and multi-system integration.

Enterprise (Global Scale): Achieving 95% Automation

Who It's For: Global organizations needing unlimited configurability and autonomous operation

What's In the Box:

- Unlimited rule configuration with site-specific variations

- Full PLM integration with complex approval workflows

- Support for custom ERP objects and unique business logic

- Advanced AI-driven automation with continuous learning

- Enterprise-grade support with dedicated solution architects

What It Means for You:

- Eliminate 95% of routine coordination work across global teams

- Cut global rollout time from weeks to hours

- Remove compliance headaches with automatic local requirements

- Save $50,000-$200,000 in avoided custom development

Sample Scenario: A Fortune 500 manufacturer with multiple PLM systems and global ERP instances achieves lights-out automation for 80% of engineering changes, freeing their 50+ engineer team to focus purely on innovation while maintaining perfect data governance across 15 countries.

How Much It Costs: Starting at $15,000 annually

Implementation Scope: 6+ months with phased rollout and custom development.

Why CADTALK Costs More Than Basic Import Tools

This is probably the most common question we hear: "Why is CADTALK more expensive than the other guy?"

The answer lies in what you're actually buying:

Basic Import Tools Give You:

- Simple field mapping

- One-way data transfer

- Manual process management

- Break during software upgrades

- Limited support for complex scenarios

CADTALK Delivers:

- End-to-end automation from engineering to shop floor

- 100% configurable platform you control yourself

- Automatic upgrade support through vendor partnerships

- Visual intelligence that prevents errors before they reach production

- Scalable architecture that grows with your business

The ROI Math: If a basic tool saves you $10,000 annually but CADTALK saves you $50,000 annually, which one actually costs more?

Consider this real example: A customer needed to update 15,000 parts for new manufacturing equipment. A basic import tool would have required weeks or even months of manual work. CADTALK processed the entire ECN in 24 hours, delivering $100,000 in immediate value. This let their engineers do the work they're paid to do and helped them use their brand new equipment right from the start.

Sound like your situation? See how CADTALK would handle your specific CAD-ERP challenges →

Your Integration Journey: Starting Smart and Scaling Up

Can you change packages after you buy CADTALK? Absolutely! Actually, we encourage it.

Most successful implementations follow this progression:

Phase 1: Prove Value (Year 1)

Start with Launch or Optimize to demonstrate immediate ROI and build internal confidence in automation. This gives your team time to fully adopt the new workflow and identify additional opportunities.

Phase 2: Expand Scope (Years 1-3)

Upgrade to Automate as processes mature and you identify additional automation opportunities. Most teams need 12-24 months to fully leverage their initial tier before scaling up.

Phase 3: Scale Globally (Years 2-5)

Move to Enterprise for complex multi-site deployments and advanced integration needs. Though it's not always the case, global rollouts and complex automation typically require 2-3 years of organizational maturity.

Key Benefits of This Approach:

- Immediate ROI at each stage

- Reduced implementation risk

- Team learning and adoption time

- Budget flexibility for growing organizations

Technical Considerations That Affect Pricing

ERP Complexity Levels

SMB ERPs (Acumatica, NetSuite, Business Central): Generally simpler data structures with standard field requirements. Implementation focuses on efficient templates and basic automation.

Mid-Market ERPs (Infor, Epicor, SAP Business One): More complex business logic requirements, custom fields, and multi-module integration needs.

Enterprise ERPs (SAP, IFS, JD Edwards): Highly customized implementations with unique business objects, complex approval workflows, and global deployment requirements.

Integration Architecture Factors

Standalone Mode: Independent application managing data flow between systems. Ideal for manufacturing teams who don't need CAD software open.

CAD-Integrated Mode: Embedded within CAD software for seamless designer workflows. Perfect for engineering-driven organizations.

Fully Automated Mode: Scheduled synchronization with minimal human intervention. Best for high-volume, standardized operations.

Implementation Variables That Affect Timeline and Cost

Faster Implementations (8-12 weeks):

- Standard ERP configurations

- Single CAD system

- Basic field mapping requirements

- Established engineering standards

Complex Implementations (6+ months):

- Custom ERP objects and fields

- Multiple CAD/PLM systems

- Advanced business logic requirements

- Multi-site deployment needs

Calculating Your Specific ROI

Here's the technical framework for evaluating your investment:

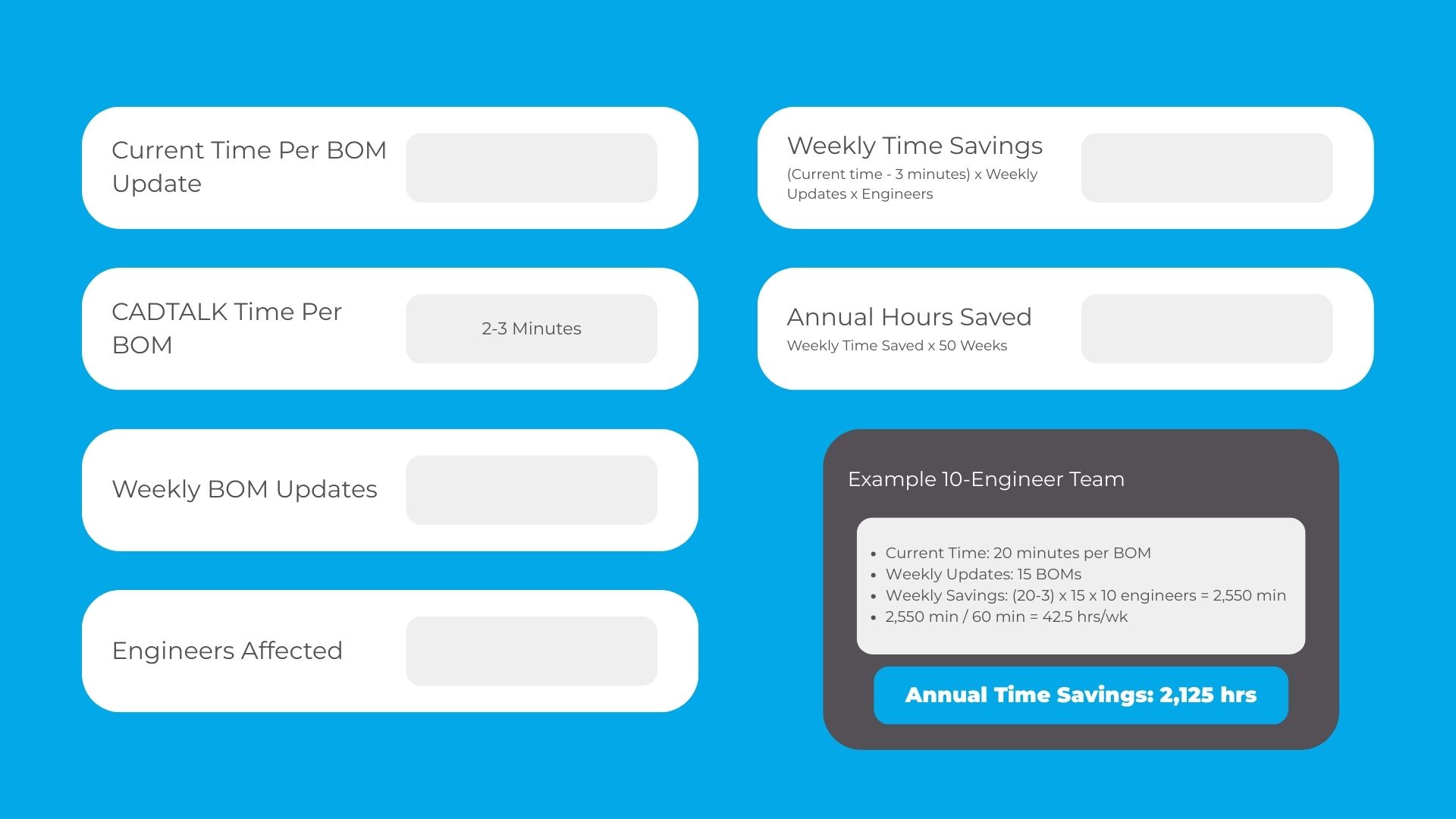

Time Savings Calculation

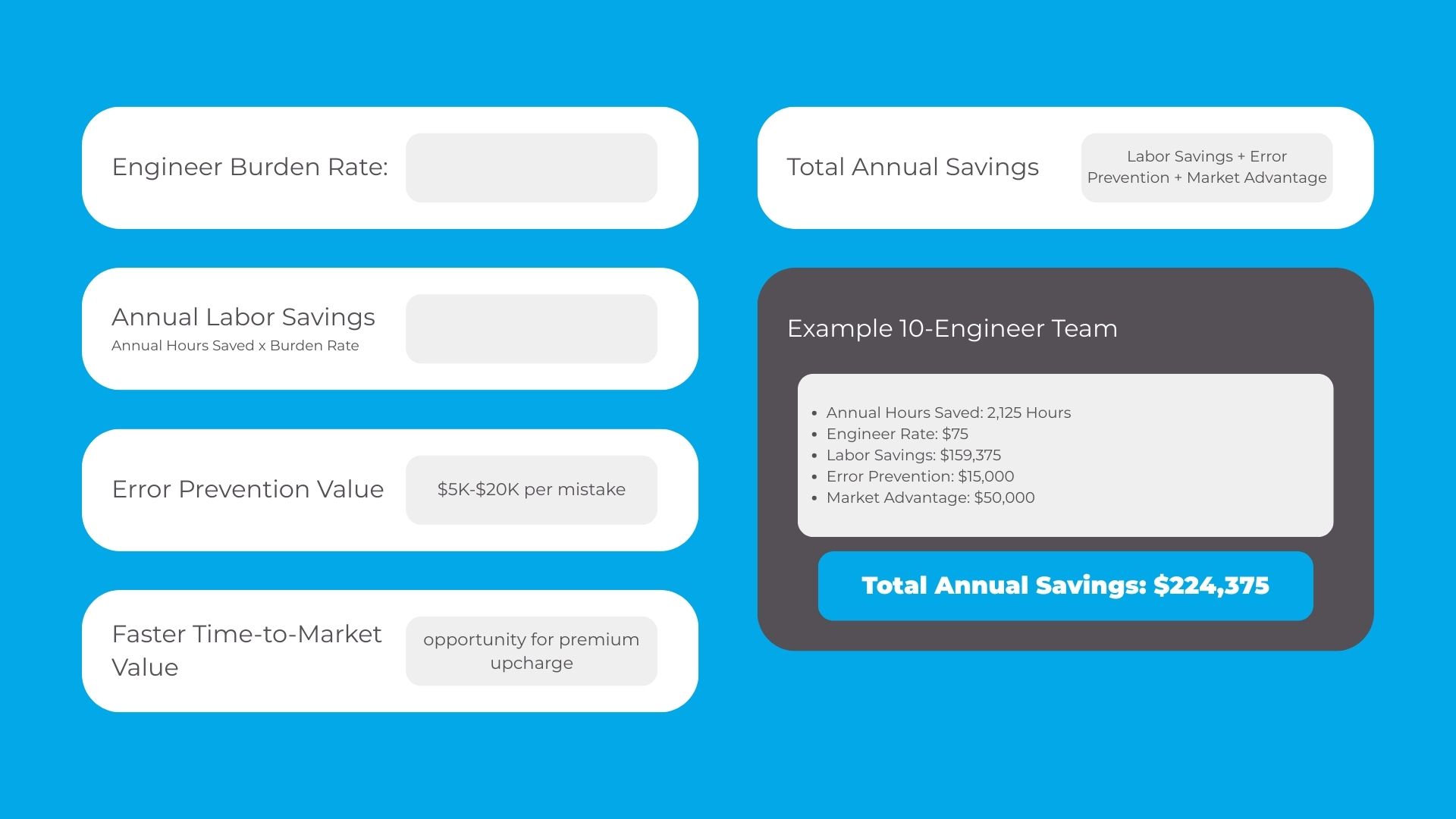

Cost Savings Calculation

Break-Even Analysis

Most customers see break-even within 6-12 months, with 3-year ROI ranging from 300% to 1,400% depending on team size and automation level.

Want to see your specific numbers? Calculate your potential ROI in 2 minutes →

Common Integration Challenges and Solutions

Challenge: "Our ERP has custom fields and objects"

Solution: CADTALK's configurable platform handles custom requirements without vendor dependency. Enterprise tier includes unlimited custom object support.

Challenge: "We use multiple CAD systems"

Solution: Add-on pricing for additional CAD systems provides unified data management across platforms.

Challenge: "Our PLM is the master system"

Solution: Bi-directional PLM support maintains design control while automating ERP updates.

Challenge: "We have complex approval workflows"

Solution: Advanced rules engine supports conditional processing and site-specific business logic.

Making the Right Choice for Your Organization

Questions to Ask Yourself:

- What's your current pain level? High manual burden suggests starting with Launch/Optimize for immediate relief.

- How standardized are your processes? Established standards enable faster implementation with pre-built templates.

- What's your growth trajectory? Rapid scaling requires more sophisticated automation capabilities.

- How complex is your technical environment? Multiple systems and custom requirements drive higher-tier needs.

- What's your automation maturity? Teams new to automation benefit from starting smaller and scaling up.

Next Steps: Getting to Your Specific Pricing

Every organization's CAD-ERP integration needs are unique. The best way to get accurate pricing is through a technical assessment that considers:

- Your specific ERP and CAD environment

- Current process pain points and inefficiencies

- Growth plans and scaling requirements

- Technical complexity and custom requirements

- Desired automation level and timeline

Ready to see exactly how CADTALK would work in your environment? Schedule a personalized demo where we'll assess your specific needs and provide accurate pricing for your situation.

Want to run the numbers first? Use our ROI calculator to see potential time and cost savings for your team.

CADTALK transforms CAD-to-ERP workflows for engineering teams worldwide, from 5-engineer startups to Fortune 500 manufacturers. Our AI-powered platform eliminates manual data entry while providing the scalability and flexibility to grow with your business.

SCHEDULE A CADTALK DEMO

Ready to see what CADTALK can do for your business? See it in action!