CASE STUDY: A DIGITAL TRANSFORMATION WITH CADTALK AND IFS

CHALLENGE

A TECHNOLOGICAL OVERHAUL: Milbank Manufacturing, a leader in producing electrical metering equipment, needed a technological overhaul. The company sought to solve two problems at once:

- Make the transition from tabulated drawings to 3D modeling

- Implement IFS as its new and upgraded ERP software.

It's a common situation we see at CADTALK. Milbank needed to integrate intelligently - but how could they do that efficiently and effectively? The company's investment of time and money needed to be worth it.

PAIN POINTS

Milbank found itself assigning all of its engineering part numbers manually. These processes were laborious, requiring multiple iterations of spreadsheets and quality checks before the manufacturing handoff occurred.

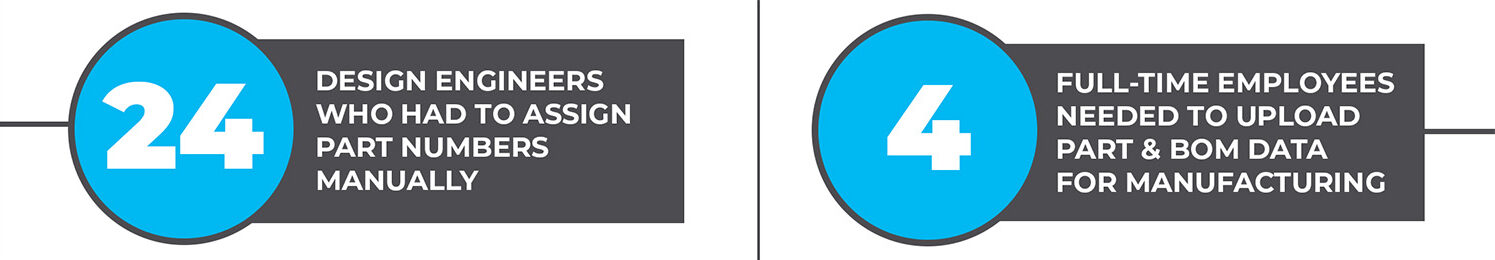

“It was a major pain point for us and a lot of our design engineers,” said Bryce Ludwig, Engineering lead on Milbank’s ERP search process. “We’ve got 24 people doing that all day long.”

Milbank also required four full-time employees to upload part data and BOM data as part of the manufacturing handoff.

Ludwig and Milbank’s leadership team needed to eliminate this inefficient use of time and resources. And everyone involved knew integrating their CAD models with their new ERP would be the most likely solution.

But finding that integration software, as well as the right ERP for it to integrate with, was critically important.

THE SEARCH PROCESS

Ludwig and team settled on IFS as their ERP of choice, which came with a recommendation for an integration software. But what did that software need to do?

We were most interested, at this point, in getting parts and bill of materials data set up in IFS quickly. We also really wanted to have great alignment with what’s in our CAD models and IFS so on the shop floor, when you’re looking at the prints and the bill of materials, it all lines up.

BRYCE LUDWIG

ENGINEERING LEAD, MILBANK MANUFACTURING

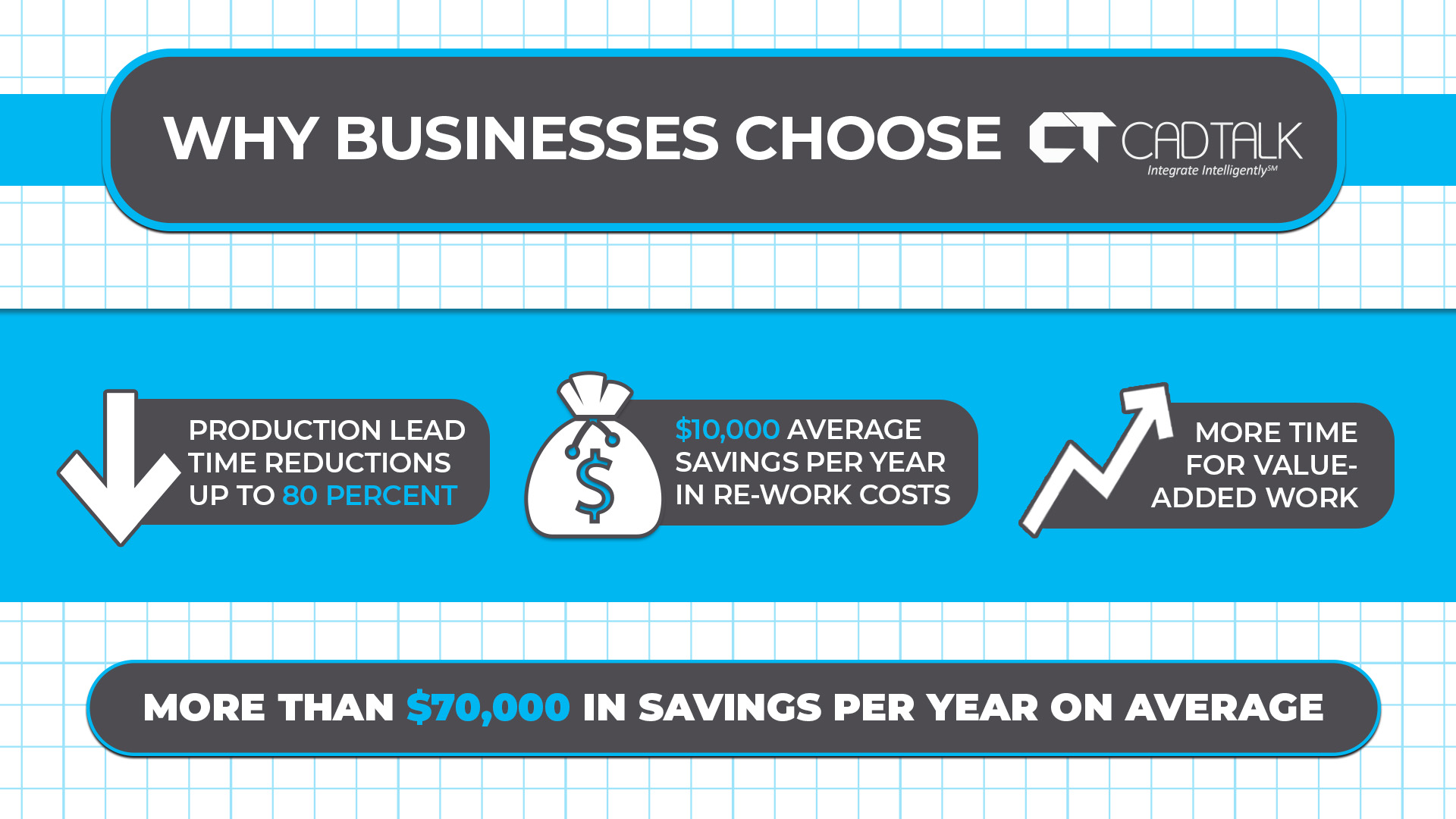

This “faithful communication” between CAD models and IFS was not happening at the time for Milbank, due to the aforementioned complexities of manual data entry. Ludwig was seeing what many other engineering leads see in manufacturing - BOM errors,

rework expenses, and wasted time and money.

Automating this data transfer between Milbank’s CAD models and IFS would all but eliminate these pitfalls. Enter CADTALK ERP.

WHAT IS CADTALK ERP?

CADTALK ERP is a completely off-the-shelf, intelligent, bi-directional integration between CAD, PDM, or PLM and IFS Apps and IFS Cloud.

CADTALK ERP reads data from any CAD, PDM, or PLM application transforming the engineering bill of materials (eBOM) into manufacturing bills of material (MBOM).

CADTALK ERP focuses on the entire engineering to manufacturing hand-off by supporting every aspect of the bill of material from engineering and inventory parts, product structures, and routings, to labor calculations, scrap percentages, vendors, manufacturers and more.

CADTALK is a Global Technology Partner with IFS, and IFS’ consultants told Ludwig that it may just be the answer Milbank needed.

IFS and a host of other ERPs choose CADTALK as an intelligent integration partner with virtually any CAD software because of its customization capabilities and the outstanding outcomes it provides.

AFTER CADTALK

Though the IFS implementation is ongoing, Milbank has already seen transformational success in optimizing its manufacturing handoff.

- Part numbers for BOMs are now automatically assigned with the push of a button.

- CADTALK reserves part numbers from IFS and then assigns them to any parts without a number.

- The four full-time employees who were uploading part and BOM data can now simply oversee the automated process and dedicate more time to other essential projects.

- Ludwig’s wish to see faithful communication between 3D modeling, prints, and IFS has been granted, allowing design intent to be conveyed accurately.

WHAT'S NEXT

Because Milbank is still implementing IFS, there are many more customizable features of CADTALK that the company can still explore.

Ludwig feels confident in the future of Milbank’s partnership with CADTALK for three

primary reasons.

- CADTALK’s ability to stay current with IFS updates - once an update is pushed, CADTALK has its software mirroring that update within weeks to a month or two, not months to years.

- The ability of his own employees to tweak property mappings without hiring a dedicated developer. CADTALK can be utilized in this way, allowing companies to keep their processes efficient with autonomy.

- CADTALK’s support is easy to work with and nimble. Ludwig found this firsthand when a custom field was added to a bill of materials that required CADTALK’s help to set up, and the process was completed within a matter of weeks.

Your team worked very quickly to get us access to those custom fields and get them set up. We were able to get through it within a couple of weeks. It was pretty fast! That was cool to find out in that moment, yes, we did choose to work with the right people on this process.

BRYCE LUDWIG

ENGINEERING LEAD, MILBANK MANUFACTURING

SCHEDULE A CADTALK DEMO

Ready to see what CADTALK can do for your business? See it in action!