LEGACY ERP INTEGRATIONS

BOM IMPORT UTILITY

Manufacturers replace their ERP software about every 10 to 15 years. During that time they accumulate a vast database of items, inventory records (items by stocking location), bills of material, routings with labor operations, and more. This data needs to be moved to the new ERP system but there are many problems with what should be a relatively simple data conversion.

First, the data is likely not 100% accurate as data entry errors are very likely over the course of 10 to 15 years of data entry across several (or several dozen) users with various experience and knowledge working with ERP. As such, the data needs to be validated before moving to the new ERP to ensure you don’t start off with bad data.

Second, the bill of material and routing format in every ERP system is slightly different. In one system they may be combined into a bill of manufacturing or method of manufacturing as a singular record containing both material and labor operations. In other ERP systems the bill of material is maintained separate from the routing with defines the labor operations with reference designators to indicate which bills of material are used for the particular labor operation. Moving from one ERP to another often forces engineers and IT staff to carefully evaluate the legacy ERP data and manually change it into a format compatible with the new ERP application. This of course can take a lot of time and slows down the ERP implementation adding unnecessary costs to the overall ERP implementation process.

Third, the legacy ERP data may be completely unusable. It could be in a format that prevents it from being migrated to the new ERP or it could be corrupt for riddled with errors that would require way too much time to correct. In these cases, the manufacture is better off to start from scratch entering the information fresh into the new ERP.

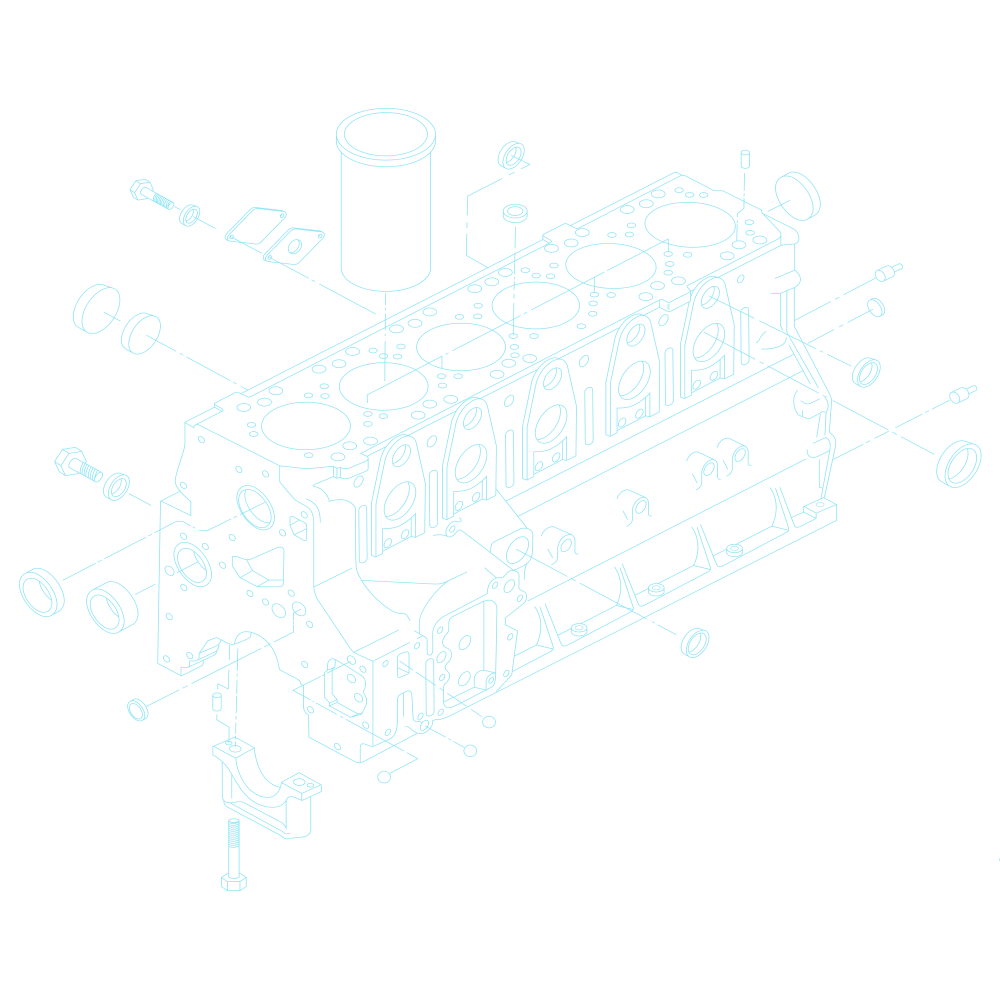

CADTALK BOM can connect to many legacy ERP applications as well as general data sources like csv files or spreadsheets to cleanse and correct data to prepare it for migration into the new ERP application. As an alternative, CADTALK can be used to create items, inventory, bills of material, and routings in you new ERP system directly from the original CAD models by leveraging artificial intelligence to fill in missing information from the engineering bill of material.

KEY BENEFITS