In today's diverse manufacturing landscape, companies employ various strategies to produce goods efficiently while meeting market demands. These approaches, known as manufacturing modes, exist on a spectrum from mass production to highly customized products.

Understanding these modes can help businesses refine their operations and make the most of their technology and investments to gain competitive advantages.

MAKE-TO-STOCK (MTS)

When you think “manufacturing,” this is probably the mode that pops into your mind. Make to Stock is the traditional manufacturing approach. In this mode, products are produced in anticipation of demand and stored until purchased.

Key Characteristics:

Typical Examples:

Consumer packaged goods, standard electronics, household items

This classic example of manufacturing serves the masses with impressive speed. It’s downside, however, is inventory risk. Do we have enough in stock? Do we have too much in stock?

In response to these risks, the MTS model has evolved significantly with technology. To the point where make-to-stock may become obsolete. The speed with which some organizations are able to manufacture has enabled them to nearly do away with MTS.

As Scott Brickler noted in our recent podcast, "One of the things that Walmart did with some of their tracking systems was turning a lot of make-to-stock into make-to-order because they were able to track transactions at checkout to trigger ordering." This data-driven approach has made MTS more responsive while reducing inventory risks.

MAKE-TO-ORDER (MTO)

In a Make to Order environment, production begins only after receiving a customer order. This reduces inventory costs but typically extends lead times.

Key Characteristics:

Typical Examples:

Furniture, machinery, specialty vehicles

MTO manufacturers often employ configurators that allow customers to select from available options. This offers the customer a more personalized experience or product. However, this usually comes at the expense of speed.

The manufacturer has little to no stock to pull from. They must respond in real time to orders as they customers submit them.

So why would someone operate like this? Often, manufacturers go for a make-to-order model because the number of variations is too large. In order to stock the right number of each possible variation, the manufacturer would take on far too much risk.

ASSEMBLE-TO-ORDER (ATO)

Assemble to Order meets MTS and MTO right in the middle. This is where components and subassemblies are manufactured to stock, but final assembly occurs after receiving the customer order.

SCHEDULE A CADTALK DEMO

Ready to see what CADTALK can do for your business? See it in action!

Key Characteristics:

Typical Examples:

Computers, automobiles, modular furniture

If you’ve ever ordered a computer online, you likely understand assemble-to-order intuitively.

Dell, for example, exemplifies the ATO approach by stocking common components like RAM and hard drives. Do you want 8 or 16 gigs of RAM? How many GPUs would you like? Would you prefer 4 or 6 core processors?

All of these subitems are stocked based on forecasting. Then, upon your order, Dell quickly assembles them based on your specific configuration. This strategy provides customization while keeping relatively quick delivery times.

ENGINEER-TO-ORDER (ETO)

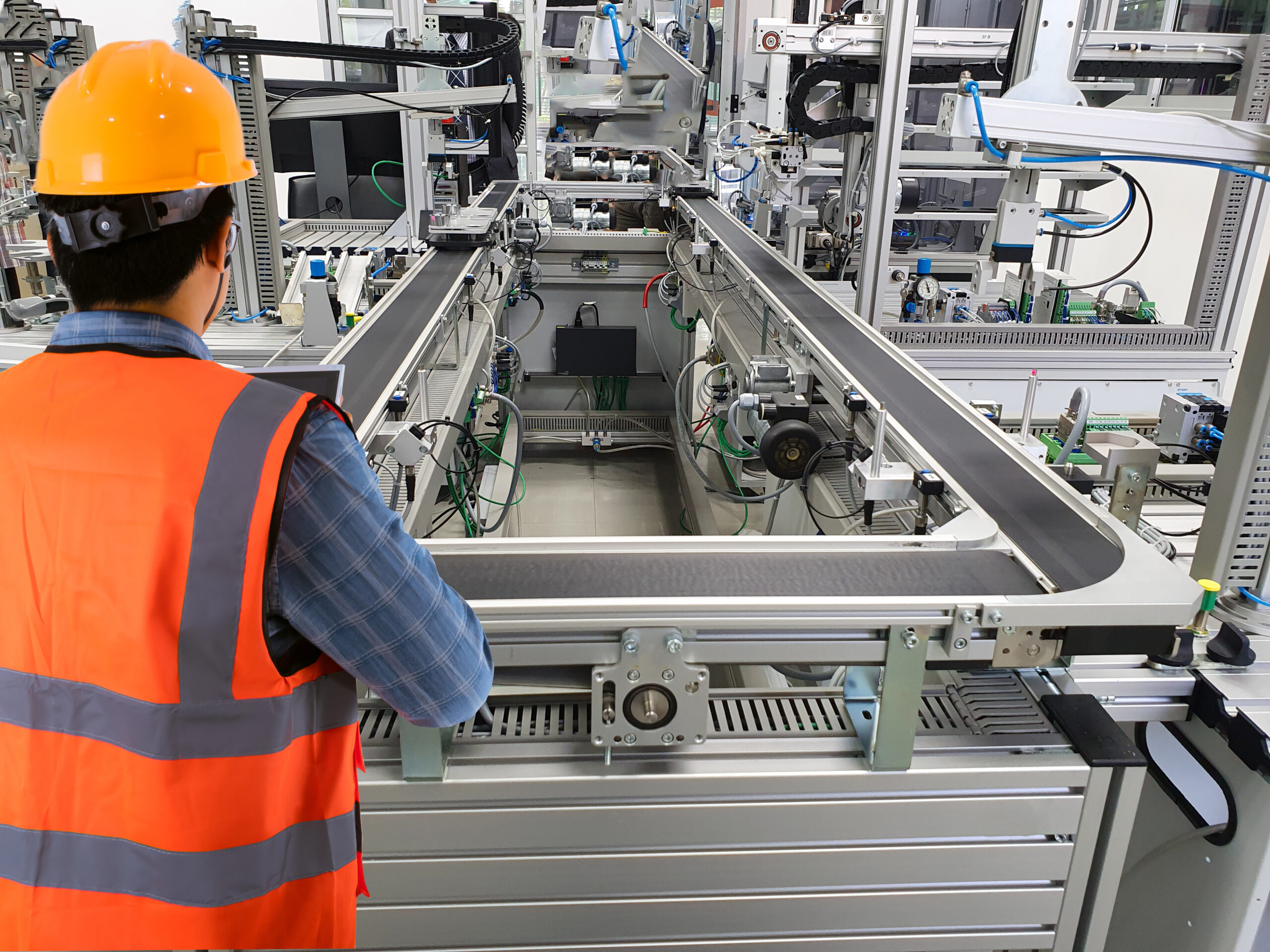

The Engineer to Order approach involves designing, engineering, and manufacturing a product specifically to meet unique customer requirements.

Key Characteristics:

Typical Examples:

Custom machinery, packaging equipment, large manufacturing systems

Again, in our recent podcast episode, Scott highlights his background in packaging machinery. "Every product that you're packaging is a little bit different. You have a lot of engineering happening. I think when I worked at the packaging company, over a third of the company was just engineers."

Sometimes, organizations don’t have the luxury of using the fastest, most cost-efficient mode. Doing so would increase their risk and cost. Where specificity and precision are most important, engineer-to-order is necessary. Otherwise, the end product would be insufficient for the customer, leading to more cost and more time.

FINDING YOUR PLACE ON THE SPECTRUM

Most manufacturers don't work purely in one mode. Instead, they exist somewhere on the spectrum and may use different approaches for different product lines. The key is understanding what you're optimizing for:

- Speed: How quickly do you need to deliver products?

- Cost: How efficiently can you manage inventory and production?

- Flexibility: How customizable are your offerings?

Cost, risk, and time need to be balanced. And it’s striking the right balance for your organization that helps you find a competitive advantage. But you must remember that things change and technologies evolve.

For example, many engineer-to-order businesses try to move toward configure-to-order approaches to reduce engineering costs while supporting customization. Similar moves have been made from made-to-stock. Having too little or too much in your warehouse is expensive.

TECHNOLOGY IMPLICATIONS

Your manufacturing mode has significant implications for your technology stack:

- ERP Systems: Different modes require different approaches to inventory management, production planning, and costing

- PLM Systems: Make-to-stock businesses often have longer development cycles with rigorous change management

- Integration Tools: The value of integration varies by mode - engineer-to-order benefits from speed of data transfer, while make-to-stock values data consistency

Understanding your manufacturing mode helps choose which technological investments will deliver the most value. If you know where you’re going, then you can more accurately pick where to put your focus.

CONCLUSION

Whether you're making standardized products for stock, assembling configurable options, or engineering custom solutions for specific requirements, identifying your manufacturing mode is essential for strategic planning. The most successful manufacturers understand their place on this spectrum and optimize their operations accordingly.

By recognizing the unique challenges and opportunities of your manufacturing mode, you can make better decisions about technology investments, production processes, and market positioning - ultimately creating a more efficient, responsive, and competitive business.